Why Robots Struggle To Create Nike Shoes: Technological Hurdles And Solutions

Table of Contents

The Dexterity Dilemma: Fine Motor Skills and Complex Assembly

Shoemaking is a surprisingly intricate process. Creating a Nike shoe involves numerous steps requiring a level of dexterity that currently surpasses the capabilities of most robots. Consider the complexity involved:

- Precise stitching of intricate patterns: Many Nike shoe designs feature complex stitching patterns that demand precision and control far beyond the reach of current robotic arms.

- Handling delicate materials like leather and mesh: The diverse materials used – leather, synthetics, mesh fabrics – vary greatly in texture, thickness, and flexibility, posing significant challenges for robotic grippers.

- Consistent application of adhesives and other materials: The precise application of glue, sealant, and other materials is critical for a high-quality, durable shoe. Inconsistent application leads to defects.

- Inspection for quality and defects: Automated visual inspection of finished shoes to identify flaws is crucial but demands sophisticated computer vision and AI capabilities.

Current robotic manipulators and grippers lack the fine motor skills and adaptability needed to reliably perform these tasks. However, research into advanced robotics offers hope. Developments in soft robotics, utilizing flexible materials and more compliant grippers, and the integration of advanced tactile sensors, which provide robots with a sense of touch, are paving the way for improved dexterity in robotic manipulation.

Material Variability: The Challenge of Non-Uniform Inputs

The diverse materials used in Nike shoe manufacturing present another significant hurdle for robot shoe manufacturing. Robots struggle with the inherent variability of these materials:

- Variations in material thickness and texture: Leather hides, for instance, vary significantly in thickness and texture, affecting cutting and stitching processes.

- Different material properties affecting cutting and stitching: The differing properties of leather, synthetics, and fabrics require adjustments to cutting pressure, stitching speed, and needle type. Adapting to these variations in real-time is a major challenge.

- The need for adaptive robotic systems: Robots need to "learn" to adjust their actions based on the specific material being processed.

Advanced vision systems and machine learning algorithms are crucial solutions. These systems can rapidly analyze the material, determine its properties, and adjust the robotic actions accordingly. AI-powered quality control systems can further improve consistency by identifying and rejecting materials that deviate from the specified parameters.

Programming Complexity: The Software Bottleneck

Programming robots to perform the numerous, intricate steps involved in shoe manufacturing is incredibly complex. It's not just a matter of issuing simple commands; it requires:

- Precise motion planning and control: Each robotic action must be precisely planned and controlled to ensure accuracy and efficiency. Errors in programming can lead to wasted materials and defective products.

- Integrating various robotic systems for seamless operation: Shoe manufacturing involves multiple robotic systems working together. Seamless integration and coordination of these systems are essential.

- Managing unpredictable variations in material and process: Robots need to be able to adapt to unforeseen variations in material properties and processing conditions.

Advanced programming languages, sophisticated simulation tools, and the application of machine learning are all essential in addressing these complexities. Machine learning can help optimize robotic processes, adapt to unforeseen circumstances, and improve overall efficiency.

Economic Feasibility: Balancing Automation and Cost

Implementing advanced robotics in shoe manufacturing requires a significant upfront investment:

- Cost of robotic systems and integration: The cost of purchasing, installing, and integrating sophisticated robotic systems is substantial.

- Training and maintenance requirements: Specialized training is required to operate and maintain these complex systems, adding to the overall cost.

- Potential for job displacement: The introduction of automation can lead to job losses, creating social and economic challenges.

However, the potential long-term cost savings and benefits of automation are considerable. Increased efficiency, reduced waste, and improved product quality can offset the initial investment. Strategies for gradual implementation, focusing on automating specific tasks initially, can help mitigate risks and maximize return on investment (ROI).

Conclusion

Fully automated Nike shoe production faces significant hurdles, including the dexterity needed for fine motor skills, the variability of materials, the complexity of programming, and economic feasibility. However, ongoing research in advanced robotics, artificial intelligence, and machine learning offers promising solutions. While complete robotic automation may be some time away, incremental advancements are steadily increasing the role of robots in shoe manufacturing.

Call to Action: The future of robot shoe manufacturing is evolving rapidly. Stay informed about the latest breakthroughs and advancements in this exciting field. Continue to explore the intricacies of robot shoe manufacturing to witness the fascinating evolution of this complex process.

Featured Posts

-

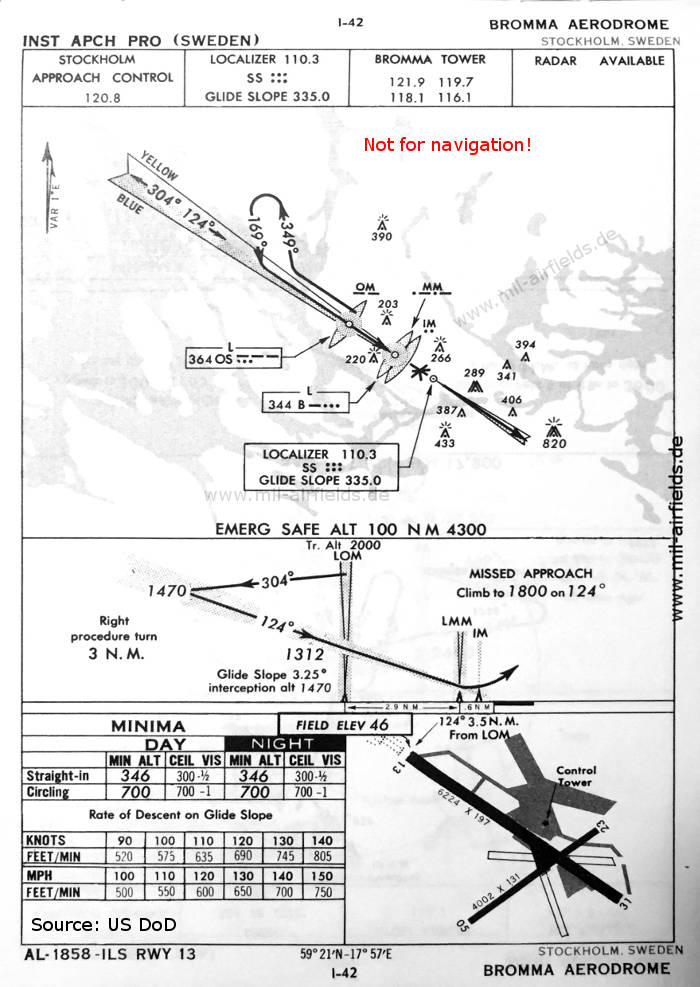

Exploring The Pan Nordic Military Alliance Swedish Tanks And Finnish Troops

Apr 22, 2025

Exploring The Pan Nordic Military Alliance Swedish Tanks And Finnish Troops

Apr 22, 2025 -

Ukraine Under Fire Russia Launches Deadly Airstrikes As Us Seeks Peace

Apr 22, 2025

Ukraine Under Fire Russia Launches Deadly Airstrikes As Us Seeks Peace

Apr 22, 2025 -

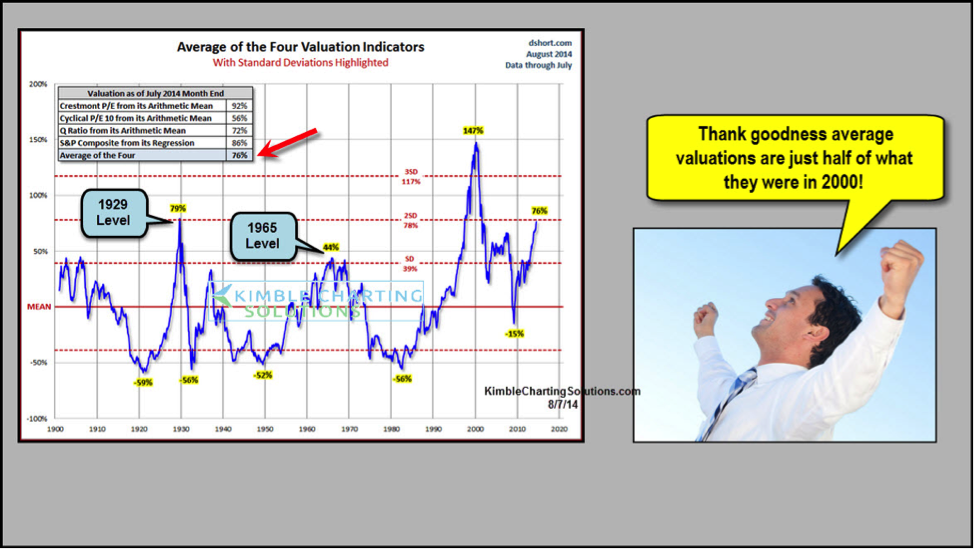

Why Investors Shouldnt Fear High Stock Market Valuations Bof As Perspective

Apr 22, 2025

Why Investors Shouldnt Fear High Stock Market Valuations Bof As Perspective

Apr 22, 2025 -

Investigation Into Persistent Toxic Chemicals In Buildings Following Ohio Train Derailment

Apr 22, 2025

Investigation Into Persistent Toxic Chemicals In Buildings Following Ohio Train Derailment

Apr 22, 2025 -

The Pan Nordic Military A Combined Approach From Sweden And Finland

Apr 22, 2025

The Pan Nordic Military A Combined Approach From Sweden And Finland

Apr 22, 2025