The Difficulty Of Automating Nike Sneaker Production

Table of Contents

The Intricate Nature of Sneaker Manufacturing

The production of a Nike sneaker is far from a straightforward process. It involves a complex assembly of numerous components, each requiring precise manipulation and assembly. This intricacy presents a significant hurdle for complete automation.

-

Precision and Dexterity: The intricate assembly process involves numerous components, including soles, uppers, laces, insoles, and various reinforcement materials. Many steps, like stitching and applying adhesives, demand a level of dexterity and finesse currently beyond the capabilities of even the most advanced robots. The delicate nature of some materials requires a level of precision and tactile feedback that robots still struggle to replicate.

-

Material Variability: Nike sneakers utilize a wide range of materials, from supple leathers and durable synthetics to intricate woven fabrics. This variability presents challenges for automated systems that require consistency in material properties for efficient operation. Adapting robotic systems to handle the diverse characteristics of these materials remains a significant technological hurdle.

-

Complex Manufacturing Process: The sneaker manufacturing process isn't simply assembling parts; it involves sophisticated cutting, molding, stitching, bonding, and finishing processes. Each step requires precise control and often involves handling delicate materials without causing damage. Replicating this level of precision and control robotically is a significant engineering challenge that impacts the overall efficiency of automated production.

High Costs and ROI Concerns Associated with Automation

While automation offers the potential for increased production efficiency and reduced labor costs, the initial investment and ongoing expenses associated with implementing automated systems in sneaker manufacturing are substantial. This significantly impacts the return on investment (ROI) and presents a considerable barrier to entry for complete automation.

-

Substantial Initial Investment: The cost of purchasing and installing robotic systems, along with the necessary infrastructure upgrades, is a major upfront expense. This high initial investment can be prohibitive for many companies, especially those with limited financial resources.

-

Ongoing Maintenance and Operational Costs: Maintaining, programming, and troubleshooting automated systems requires specialized expertise and incurs ongoing operational costs. Potential downtime due to equipment malfunctions can further increase these expenses, impacting overall productivity and profitability.

-

Labor Costs vs. Automation Costs: A thorough cost-benefit analysis is crucial before implementing automation. This analysis needs to compare the current labor costs with the total cost of automation, including the initial investment, ongoing maintenance, and potential losses from downtime. Only a comprehensive cost-benefit analysis can determine whether automation offers a superior ROI compared to existing manual processes within the sneaker manufacturing process.

The Role of Skilled Labor and Existing Infrastructure

The footwear industry relies heavily on skilled workers with expertise in traditional manufacturing techniques. Transitioning to complete automation requires significant adjustments to the workforce and existing infrastructure, presenting additional challenges.

-

Workforce Adaptation and Reskilling: Existing factories often have established supply chains and a workforce proficient in traditional manufacturing. Complete automation may require retraining existing employees or hiring individuals with specialized skills in robotics and automated systems maintenance. This reskilling initiative requires significant investment in training programs and can lead to temporary disruptions in production.

-

Integrating Automation into Existing Infrastructure: Integrating new automated systems into existing factory infrastructure can be a complex and costly undertaking. This process often requires significant modifications to the factory layout and existing equipment. These upgrades can cause temporary disruptions in production, impacting output and potentially leading to increased costs.

-

The Ongoing Need for Skilled Workers: Even with automation, a skilled workforce remains crucial. Experts are needed for maintaining, repairing, and programming the robotic systems. The demand for skilled technicians to support and oversee the automated production lines underscores the ongoing importance of human capital even in automated factories.

The Challenge of Adaptability and Customization

Nike's focus on mass customization and the release of limited-edition sneakers further complicates the automation process. The need to adapt quickly to changing designs and production volumes necessitates flexible automation solutions that are still under development.

-

Flexible Automation for Customization: Current automation solutions often struggle with the flexibility required to handle rapid changes in product design and production runs. The demand for personalized sneakers requires manufacturing processes capable of adapting to diverse product designs and volumes, which is a significant challenge for even the most advanced automation systems.

-

Balancing Mass Production and Customization: The need to balance mass production with personalized products poses a major hurdle for automation implementation. Finding an efficient and cost-effective way to automate production while maintaining the ability to offer customized products remains a key challenge for the footwear industry.

Conclusion

Fully automating Nike sneaker production faces substantial challenges stemming from the intricate manufacturing process, high automation costs, the need for skilled labor, and the demand for customization. While robotic automation plays a growing role in streamlining certain aspects of production, such as automated stitching or sole attachment, complete automation remains a distant prospect. The complex interplay between technology and the human element in manufacturing will continue to shape the future of Nike sneaker production.

Call to Action: While the complete automation of Nike sneaker production may be a long-term goal, ongoing innovation in robotics and manufacturing processes continues to offer opportunities for increased efficiency and optimized production lines. Stay informed about the latest advancements in automated production and the evolving landscape of footwear manufacturing. Understanding the difficulty of automating Nike sneaker production highlights the ongoing need for collaboration between technological innovation and the skilled workforce essential to this complex industry.

Featured Posts

-

The Difficulty Of Automating Nike Sneaker Production

Apr 22, 2025

The Difficulty Of Automating Nike Sneaker Production

Apr 22, 2025 -

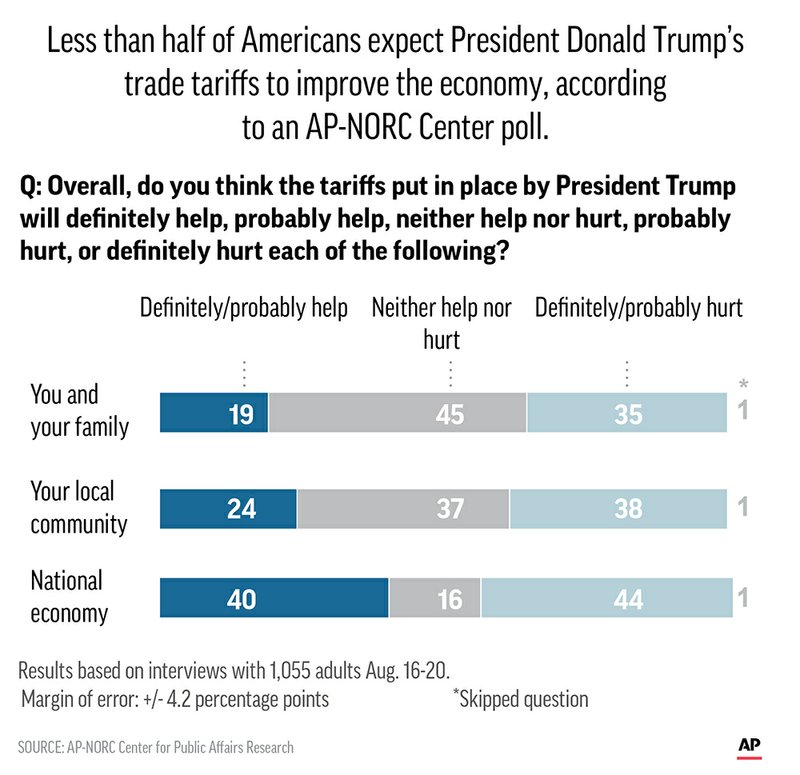

Navigating Trump Tariffs The Tik Tok Factor

Apr 22, 2025

Navigating Trump Tariffs The Tik Tok Factor

Apr 22, 2025 -

Coordinating Deportees Return To South Sudan A Us Government Partnership

Apr 22, 2025

Coordinating Deportees Return To South Sudan A Us Government Partnership

Apr 22, 2025 -

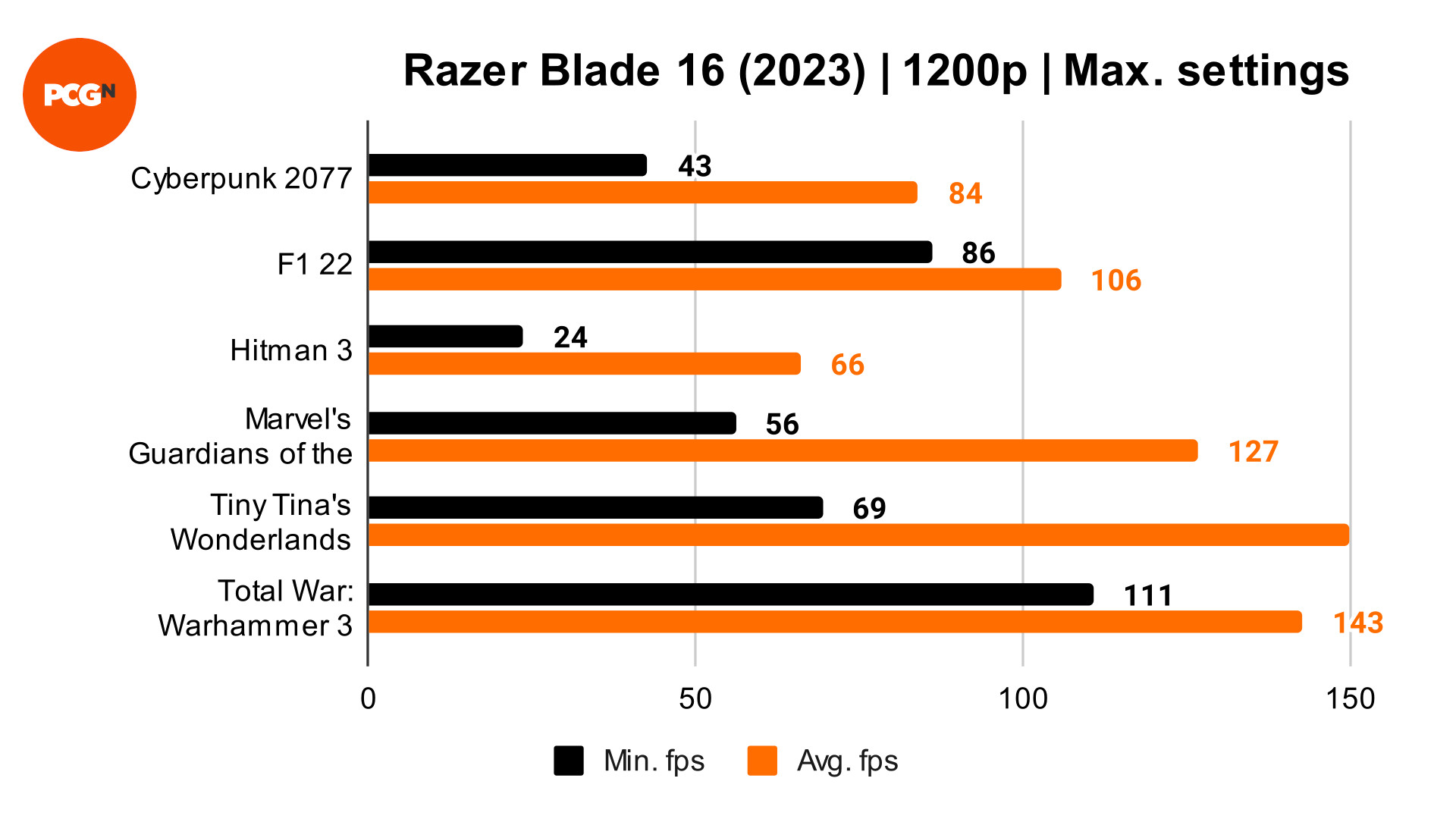

Is The Razer Blade 16 2025 Worth It A Comprehensive Review

Apr 22, 2025

Is The Razer Blade 16 2025 Worth It A Comprehensive Review

Apr 22, 2025 -

Sweden And Finlands Military Integration A Pan Nordic Defense Strategy

Apr 22, 2025

Sweden And Finlands Military Integration A Pan Nordic Defense Strategy

Apr 22, 2025