Why Nike Shoe Manufacturing Remains A Challenge For Robots

Table of Contents

The Complexity of Shoe Construction

The construction of a Nike shoe is far more intricate than it appears. The precision and dexterity required for many steps make it a difficult process to automate completely.

Dexterous Manipulation and Fine Motor Skills

Robots struggle with the intricate tasks requiring fine motor skills, like stitching, gluing, and precisely placing components. The variability in materials used in different Nike shoe models and the need for adaptability pose significant challenges for robotic precision.

- Human dexterity in handling delicate materials is unmatched by current robotic technology. The subtle pressure and nuanced movements required for tasks like stitching leather or attaching intricate embellishments are difficult for robots to replicate consistently.

- The need for adapting to different shoe designs and materials requires sophisticated AI that is still under development. A robot programmed for one type of shoe might not be able to handle a different design without extensive reprogramming.

Variety of Materials and Processes

Nike shoes utilize a wide array of materials – leather, synthetics, textiles, foams – each requiring different handling techniques. The manufacturing process itself involves numerous steps, from cutting and sewing to assembling the midsole and outsole, then finally finishing and quality control.

- Programming robots to handle this diverse range of materials and processes is computationally intensive. Each material requires unique robotic parameters for optimal handling and processing, adding significant complexity to the programming process.

- Integrating multiple robotic systems for a seamless production flow presents complex logistical challenges. Coordinating the actions of multiple robots working in tandem, each with its specialized tasks, requires sophisticated control systems and advanced AI.

The Economic Factors Inhibiting Automation

Beyond the technical challenges, economic considerations play a crucial role in slowing down the adoption of complete automation in Nike shoe manufacturing.

High Initial Investment Costs

Developing and implementing advanced robotics systems for shoe manufacturing is incredibly expensive. This includes the cost of specialized robotic arms, advanced vision systems, AI software, and the infrastructure to support it all. The return on investment (ROI) can be uncertain, particularly considering the need for ongoing maintenance and upgrades.

- Smaller manufacturers may find the financial burden of automation prohibitive. The high upfront costs make it challenging for smaller companies to compete with larger players who can absorb the investment more easily.

- The cost of specialized robotic arms and AI software remains a significant barrier. These are not off-the-shelf technologies and require considerable research and development investment.

Labor Costs and Global Manufacturing

In many regions, labor costs remain relatively low, making automation less economically attractive in the short term. Nike's global manufacturing network relies on diverse labor pools with varying skill levels and costs.

- The need to retrain workers and manage potential job displacement adds to the economic complexity. Introducing automation requires careful planning to mitigate potential social and economic consequences.

- Global supply chain disruptions can also affect the cost-effectiveness of automation. Unexpected delays or shortages can impact the return on investment of automation projects.

Technological Limitations in Robotic Shoe Manufacturing

Despite rapid advancements, current technology still faces limitations in handling the nuanced aspects of shoe manufacturing.

Adaptability and AI Challenges

Robots struggle to adapt to unforeseen variations in materials and production processes. Developing robust AI systems that can handle the unpredictable nature of manual tasks is an ongoing challenge.

- Current AI lacks the level of situational awareness and problem-solving capabilities of human workers. Humans can easily adapt to unexpected situations, while robots need explicit programming to handle variations.

- Advances in machine learning and computer vision are needed to overcome these limitations. Improved AI systems can enable robots to better understand and respond to variations in materials and processes.

Sensor Technology and Feedback Mechanisms

Precise sensor feedback is crucial for robots to perform delicate tasks with accuracy and consistency. Developing sensors capable of providing real-time feedback in the complex environment of shoe manufacturing is challenging.

- Improved sensor technology is needed to enhance robotic precision and reduce error rates. More sophisticated sensors can help robots better understand the forces and pressures involved in each task.

- Integrating advanced sensor data with AI algorithms is key to improving robotic performance. Combining sensor data with AI-powered decision-making can enable robots to make finer adjustments and improve accuracy.

Conclusion

While advancements in robotics are constantly pushing the boundaries, fully automating Nike shoe manufacturing remains a significant challenge. The complexity of shoe construction, economic considerations, and technological limitations all contribute to this ongoing struggle. However, ongoing research in areas like AI, sensor technology, and robotic dexterity holds the potential to overcome these hurdles in the future. Continued investment and innovation in Nike shoe manufacturing automation are crucial for increasing efficiency and exploring new possibilities within the footwear industry. The future of footwear manufacturing might be automated, but getting there requires continued breakthroughs in technology and economic feasibility.

Featured Posts

-

Court Battle Resumes Dojs Antitrust Case Against Googles Search Dominance

Apr 22, 2025

Court Battle Resumes Dojs Antitrust Case Against Googles Search Dominance

Apr 22, 2025 -

Trump Administration To Slash Another 1 Billion In Harvard Funding Amid Growing Tensions

Apr 22, 2025

Trump Administration To Slash Another 1 Billion In Harvard Funding Amid Growing Tensions

Apr 22, 2025 -

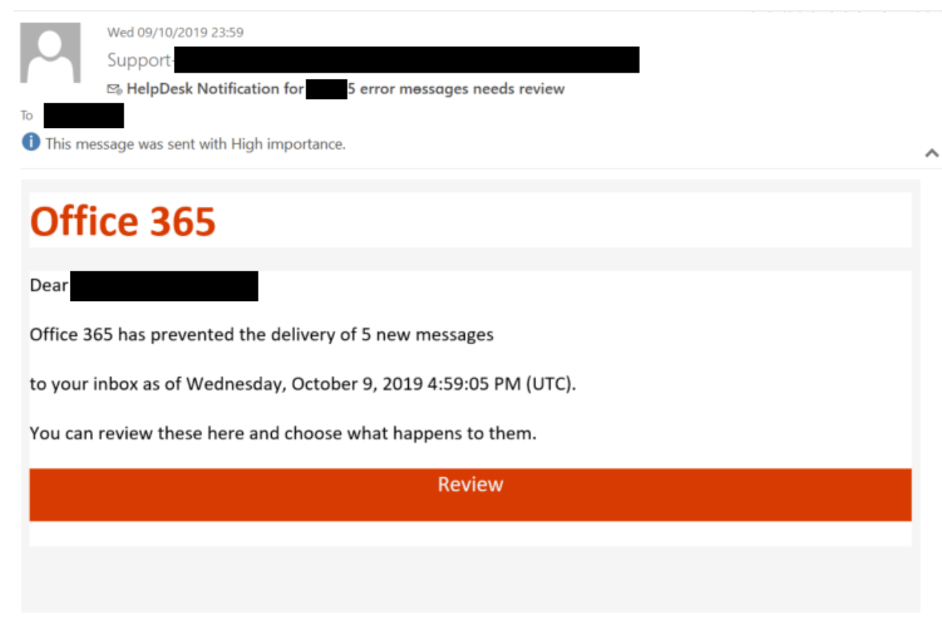

Cybercriminal Made Millions Targeting Executive Office365 Accounts

Apr 22, 2025

Cybercriminal Made Millions Targeting Executive Office365 Accounts

Apr 22, 2025 -

White House Cocaine Found Secret Service Concludes Investigation

Apr 22, 2025

White House Cocaine Found Secret Service Concludes Investigation

Apr 22, 2025 -

Harvard Faces 1 Billion Funding Cut From Trump Administration

Apr 22, 2025

Harvard Faces 1 Billion Funding Cut From Trump Administration

Apr 22, 2025